Global organizations including workforces within the wind industry, have had to grapple with the life-changing and challenging impact of COVID-19 in the past few months. Many of us may be facing times ahead that are ambiguous, uncertain, and unpredictable. Beyond these concerns, the call for social distancing measures have also pushed companies towards adequately preparing themselves for remote work, possibly for an indefinite or extended timeframe in order to maintain business continuity in the face of COVID-19. In these current uncertain times, many in the wind industry are having to navigate the pandemic to find ways forward and to continue delivering clean, affordable and reliable electricity across the country and the world.

Front-line medical workers currently have the most exposure to occupational risks and their valiant efforts have to be recognized. Wind operations and maintenance (O&M) teams are our essential front-line workforce in keeping the lights on for millions, in order to mitigate challenges brought about by COVID-19 and weathering future economic repercussions caused by its impact. Digital cloud-based O&M platforms that offer asset O&M management become more critical tools in increasing wind competitiveness, improving safety and reducing maintenance costs for critical components, such as the rotor blades. Organizations will have to invest in and accelerate critical processes and infrastructure that democratizes data and access to it when the majority of the workforce is remote. Democratizing data includes providing equal access to the same data, and empowering everyone in an organization to use data at any time to make decisions and/or take an action.

The Benefits of Digitizing and Centralizing O&M Data

Digital cloud-based platforms utilizing digitized blade O&M data and workflows will lead to smarter ways of working together through this crisis, reducing uptower visits for inspections/repairs for site personnel, requiring less travel by engineering and management personnel to follow up on results, and in getting ahead of deferred maintenance. Data centralization of digital blade O&M data goes beyond just easy accessibility, however. There are many additional benefits when combined with digital maintenance workflow management that become even more important when uniting a remote workforce:

- Single-source of truth. Data centralization provides a single source of truth for all, ensuring access and the latest understanding of the blade asset’s condition, no matter where the data is accessed. Everyone in the organization can trust the data and make confident decisions about blade inspections, repairs and continuous monitoring. Asset/operations managers and engineers will always have a pulse on their blade assets and can plan for future repairs.

- Increased consistency. Users have a centralized location for blade damage data storage, cleansing, organization, interpretation, analysis, and reporting. When everyone is working with the same blade data and insights, it improves quality and consistency throughout the organization so that repair decisions are made based on key insights and analytics, and are more transparent to other departments.

- Enhanced collaboration. O&M/site managers, operations/blade/reliability engineers, site personnel, and external repair vendors have a tool to collaborate more effectively across a decentralized organization or workforce. This then enables breaking down data silos that may inhibit optimal operations. This includes a platform to share photos, videos, documents that provide remote instruction or troubleshooting between engineering experts and specialty site repair technicians, further avoiding the need for an expert engineer to travel to site.

Data centralization provides a single source of truth for all, ensuring access and the latest understanding of the blade asset’s condition, no matter where the data is accessed.

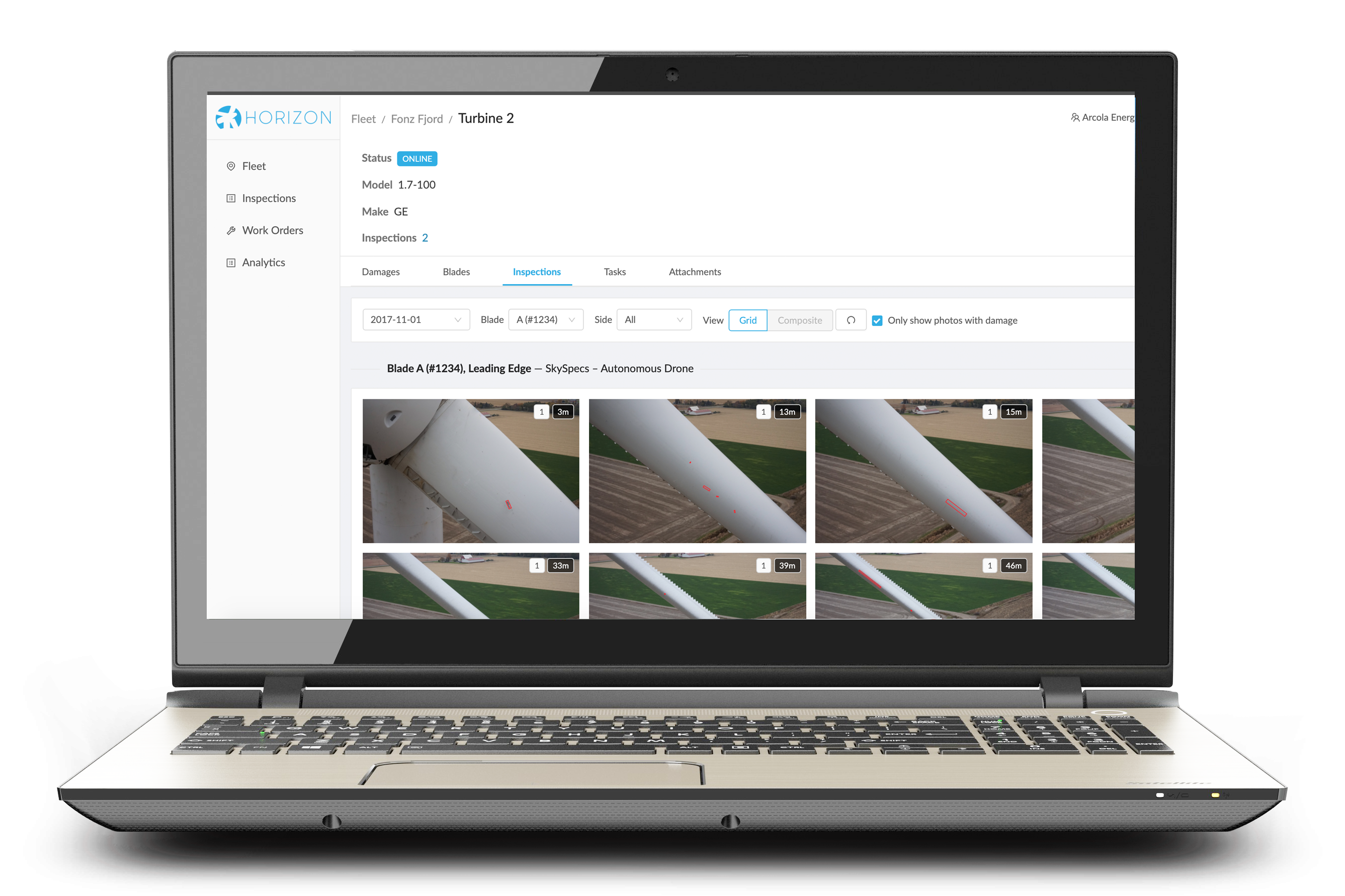

- Optimized data as an asset. Centralized blade O&M data generated from multiple and often disparate sources (e.g. drone inspections, internal blade inspections, 3rd party generated inspection and repair reports) can be used to make better decisions. When data is decentralized and disorganized, it can hinder workflows and processes. However, when data is aggregated, processed and managed within a centralized platform like Horizon, it can be cleansed and optimized for more effective use by an organization. This data repository becomes an asset that will enable organizations to make data-driven decisions on blade assets quickly around scheduled and unscheduled blade repairs, rather than relying on e-mail systems or paper-based workflows. Management can also have increased daily overview and management of blade maintenance teams and tasks. This can further reduce any risk of repair downtime and avoiding additional site or uptower visits.

- Attention and focus on what’s important. When all of the blade asset’s data is processed, cleansed, analyzed and reported in one location, staff will spend less time on data organizing and more time focusing on achieving business and operational goals. This promotes more strategic thinking on how to improve organizational processes and decisions on the right O&M actions to be implemented for preserving long-term asset health. Digital maintenance and repair workflows enable teams to communicate more effectively with a focus on prioritizing and executing the most critical corrective actions that prevent catastrophic blade failures, delaying preventative maintenance and having to work around limited repair labor/financial resources or site accessibility to 3rd party’s or subcontractors’ technicians, during this crisis.

- Saves time & money. Centralizing all of the blade health asset’s data in a cloud-based platform like Horizon also comes with the added benefit of reducing reporting times and the ability to digitally manage O&M workflows. This means key personnel are able to visualize and make sense of the data in a more legible, visible and simplified format, then make decisions on the necessary actions.

Why is now the best time to consider centralizing data?

Digital systems offering analytics on blade damage data and repair metrics also provide engineers and managers tools to adopt more predictive and condition-based maintenance strategies and to quickly prioritize and schedule the deferred repairs, as it is likely that as restrictions are slowly lifted, a large backlog of deferred maintenance activities will emerge. In this way, any additional time saved can be dedicated to adequately preparing for future repair campaigns that will allow teams to get ahead when time and financial resources allow, while avoiding machines to be offline when energy demands rise and economic activity recovers.

Companies can save on resources as centralized data also reveals inefficiencies within current business processes/practices.

Now may be the time to place focus and attention on accelerating the digitization of blade O&M data and work practices, as we continue to build resilience in managing this crisis and coming out much stronger than we all were going in. Each stakeholder has a pivotal role in leading their organization through the age of digital transformation in blade O&M. Leveraging centralized blade data and digital workflow management systems lead to meaningful and consistent reporting, reducing uncertainty about the current blade asset’s conditions when shared across the organization. This enables smarter and collaborative work practices, allowing us to find solace in that COVID-19 is a short term crisis in comparison to the long-term competitiveness of wind which will prevail.

Contact SkySpecs to learn more about Horizon Blade Management and to find out how your business can benefit from our services in data digitization and centralization.