In the vast landscape of renewable energy, wind power stands out as a leading force in the transition towards sustainable energy production.

Behind the rotation of wind turbines is a wealth of operational data, offering invaluable insights into wind turbine performance and efficiency. Traditionally, SCADA aggregate data has been collected and analyzed at 10-minute intervals, providing a balance between volume and detail. However, the need for more detailed insights has led to the adoption of high-frequency SCADA data.

The Need for High-Frequency SCADA Data

Although manufacturers often use higher-frequency data in the turbine’s control algorithms, this level of detail has not been widely available to wind farm owners or asset managers. However, as data-driven decision-making becomes increasingly important and advancements in data analysis and storage technology grow, the interest in leveraging higher-frequency datasets is expanding.

Access to such data allows wind turbine operators to gain deeper insights into turbine performance, identify potential issues earlier, and make more informed operational decisions.

To address this opportunity, the SkySpecs Performance team focused on identifying a generic approach that could be applied across a wide range of turbines. By analyzing high-frequency rotor speed signals—a key component of the rotor monitoring system—aims to address rotor imbalance monitoring, a component that is often under-analyzed in conventional asset monitoring practices.

Rather than adopting a “store everything and find use cases later” approach, SkySpecs emphasizes the importance of designing data analysis with specific, end-to-end use cases in mind. This use-case-driven approach has proven more efficient and effective, enabling the development of a practical imbalance detection metric that integrates seamlessly with existing asset management workflows and delivers actionable insights.

The Method of Creating an Imbalance Metric

The spectral analysis of high-frequency rotor speed signals is a well-established method within academic circles for identifying imbalances in wind turbines. However, its adoption in wider industrial practice remains limited. This method offers an indirect way of assessing imbalance, which means the root cause of the issue—whether mass imbalance or aerodynamic imbalance—cannot be directly identified. Both, mass imbalance from uneven mass distribution during manufacturing or gradual water ingress and aerodynamic imbalance as a result from pitch offsets that lead to uneven torque intake on the blades, show the same effects on the rotor imbalance. Despite its indirect nature, spectral analysis provides valuable insights and can serve as an early warning system for potential rotor issues.

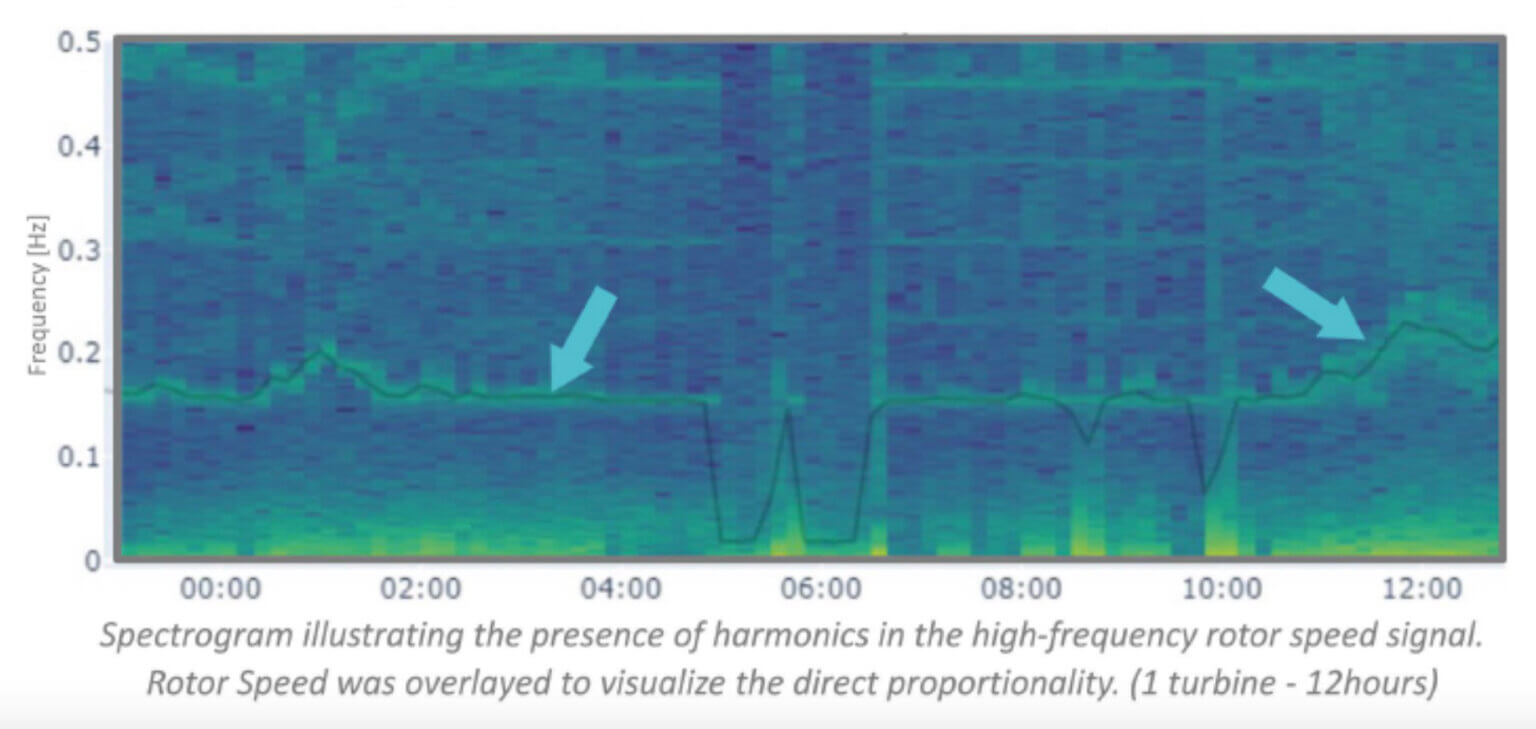

When imbalanced, the rotor vibrates at a frequency directly proportional to its speed of rotation. The new metric relies on a standard spectral analysis:

- Measure the 1p component in rotor speed using Fast Fourier Transform (FFT), corresponding to oscillations once per full rotation. Higher amplitude indicates higher imbalance.

- Use order tracking for varying rotor speed, providing robust estimation of the 1pm amplitude. If unavailable, convert generator speed to equivalent rotor speed.

- Derive amplitude using Signal-to-Noise Ratio (SNR) concepts.

- Compute the 1p amplitude every 10 minutes to ensure compatibility with existing SCADA data and facilitate comparative analysis among turbines.

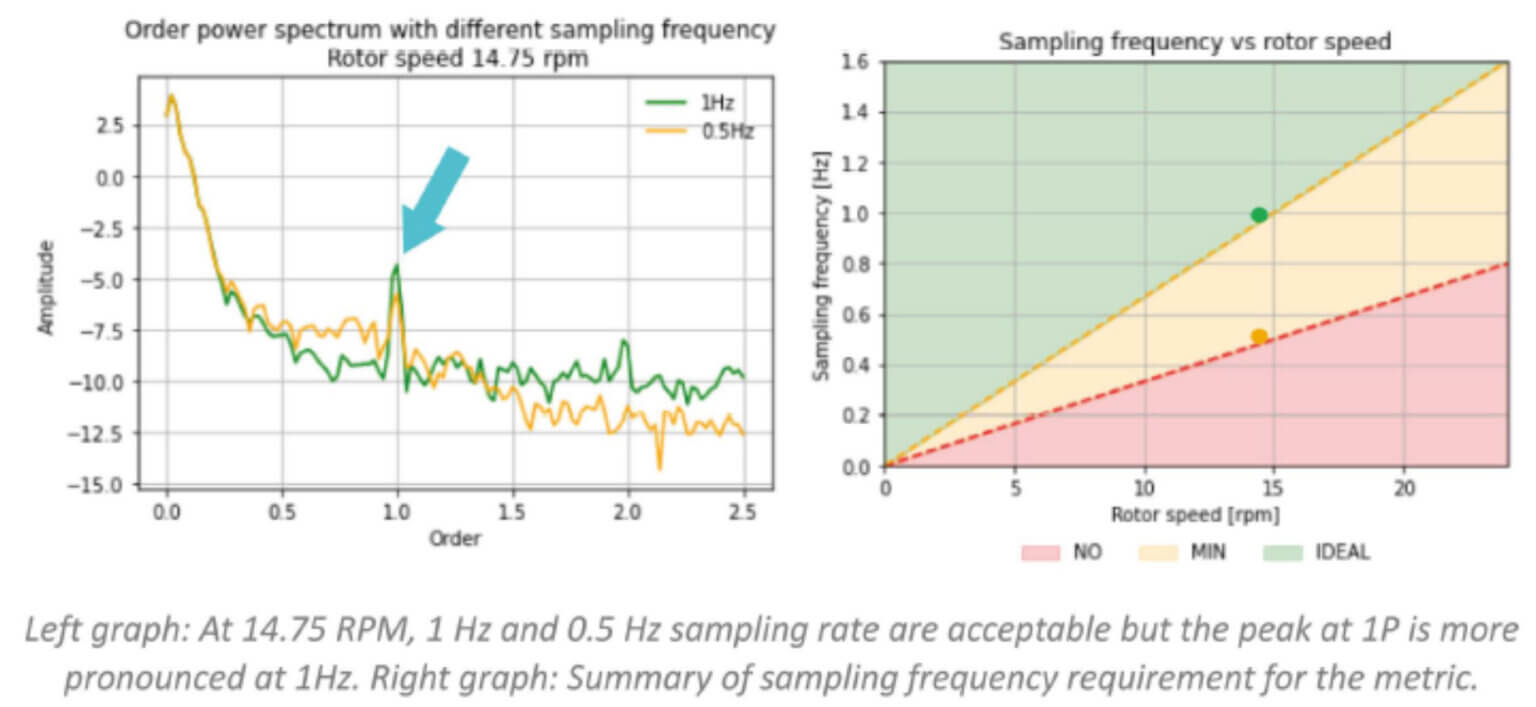

Optimal Sampling Frequency

The Nyquist-Shannon sampling theorem dictates that at least 2 points per revolution are needed to avoid aliasing , but ideally, a sampling frequency should provide twice that amount, 4 points per full rotor rotation. Given the range of RPM of a turbine, we only compute the metric when 1hz data are available.

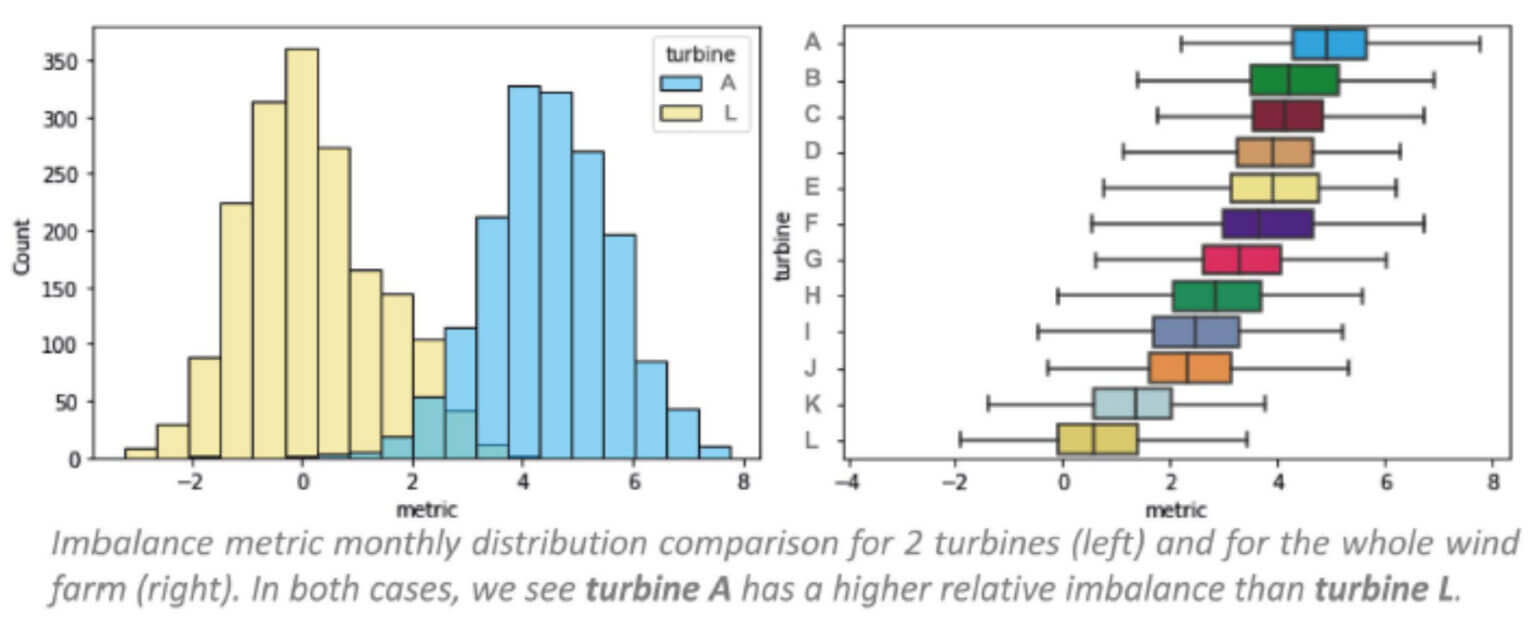

Results: Distribution & Time Series

The imbalance metric, calculated at 10-minute intervals, was further analyzed by evaluating the statistical distribution of each turbine monthly. This approach allowed for meaningful comparisons between turbines as long as they shared a similar high-frequency rotor speed sampling rate. By aggregating and examining this data, the analysis uncovered patterns that may otherwise remain hidden in standard 10-minute SCADA data.

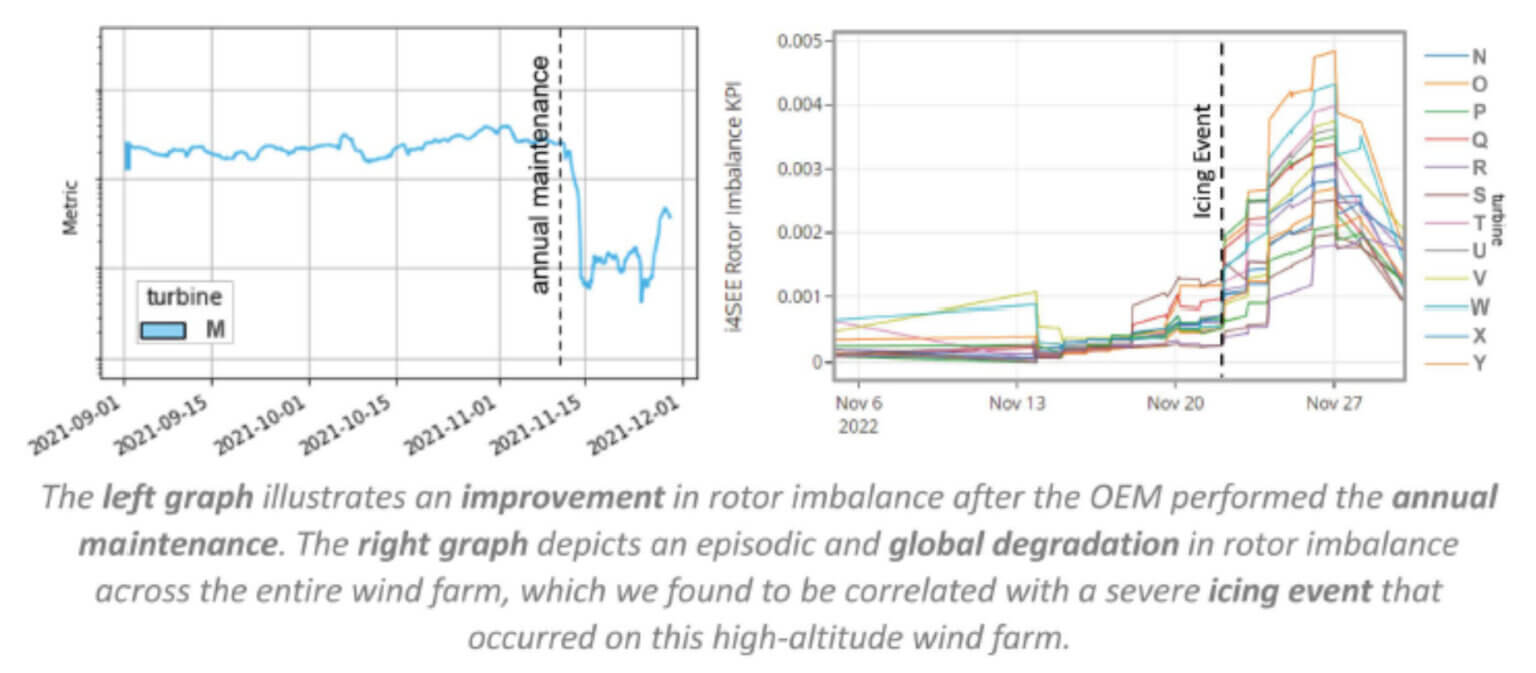

Monitoring trends at the portfolio level provides valuable operational insights, helping identify turbines likely to experience gradual deterioration or specific health issues in the rotor system. This analysis enhances wind energy data analytics and enables operators to prioritize inspections and plan maintenance more effectively. It also allows for a comparative understanding of turbine performance across a wind farm, flagging those that may require further investigation.

Furthermore, by tracking the monthly time series of the imbalance metric, operators can correlate fluctuations in the amplitude of imbalance with on-site events, such as extreme weather, icing conditions, or maintenance activities. These correlations add another layer of context to the imbalance data, helping asset managers to better understand the root cause of anomalies.

By identifying and analyzing anomalies in rotor imbalance, asset managers are empowered to make data-driven decisions regarding the tIdentifying and analyzing anomalies in rotor imbalance empowers asset managers to make data-driven decisions regarding the timing and effectiveness of interventions or retrofits. This actionable insight ensures operational efforts are targeted, timely, and efficient.iming and effectiveness of interventions or retrofits. This actionable insight ensures that operational efforts are targeted, timely, and efficient.

Elevate Your Wind Turbine Operations with SkySpecs

Harnessing high-frequency SCADA data can significantly enhance wind turbine performance and reduce operational costs. SkySpecs leads the way in transforming this data into actionable insights, enabling early detection of rotor imbalances and seamless integration into your existing wind farm asset management processes.

Our tailored solutions empower you to make informed decisions and optimize your wind farm’s efficiency. Partner with SkySpecs to unlock the full potential of your operations.

Interested in learning more? Connect with one of our experts to discover how our expertise can support your journey toward more efficient and sustainable energy production.

To explore how this model can be applied to your wind turbine fleet, schedule a consultation with our SCADA experts today.