Condition monitoring software for your entire fleet

Today, Wind turbine fleets consist of mixed brands and models spanning decades of wind turbine evolution. Some were born with advanced drivetrain sensor systems, others were retrofitted later in life, and some only have SCADA systems. How do you scale your analytics when each sensor system needs a bespoke stack of expert tools, and highly trained engineers to use them? How do you effectively drive O&M action and maximize the value of condition-based maintenance across your entire fleet?

Horizon CMS unifies your sensor data

Horizon CMS is a modern and secure cloud platform for large-scale wind turbine condition monitoring. It was built from the ground up to be multi-brand and sensor hardware agnostic. Use it for 10 turbines or 10,000 – The more you add, the more efficiency and value you get.

Kaleidoscope™ AI drivetrain fault detection technology

Early detection AND low false alarm rate?! Kaleidoscope™ AI delivers unprecedented predictive performance and intuitive diagnostic hints to help users validate detections.

Kaleidoscope™ AI Sensor Health Model

Highlight data outages, and sensor failure modes. Bad measurements are automatically detected and filtered out from failure predictions and diagnostic plots.

Kaleidoscope™ AI Classifiers

A deep neural network predictive AI model trained on a curated sensor database of recorded fault signatures. They mimic human expert eyes to identify failure mode signatures from diagnostic plots, and step changes in failure mode progression. These AI models are self-calibrating, and require zero configuration maintenance from end users.

Kaleidoscope™ AI Indicators

Provide failure mode indicators that are easy to understand and compare. Site statistics are built-in, so users can quickly assess current severity levels.

Drastic Reduction of Alarm Complexity

Traditional drivetrain CMS systems often have thousands of uniquely configured alarm mechanisms per turbine, leading to inefficient workflows. Kaleidoscope™ AI achieves complete failure mode coverage, using far fewer alarm mechanisms. Horizon CMS further enhances efficiency with streamlined, and powerful alarm workflows.

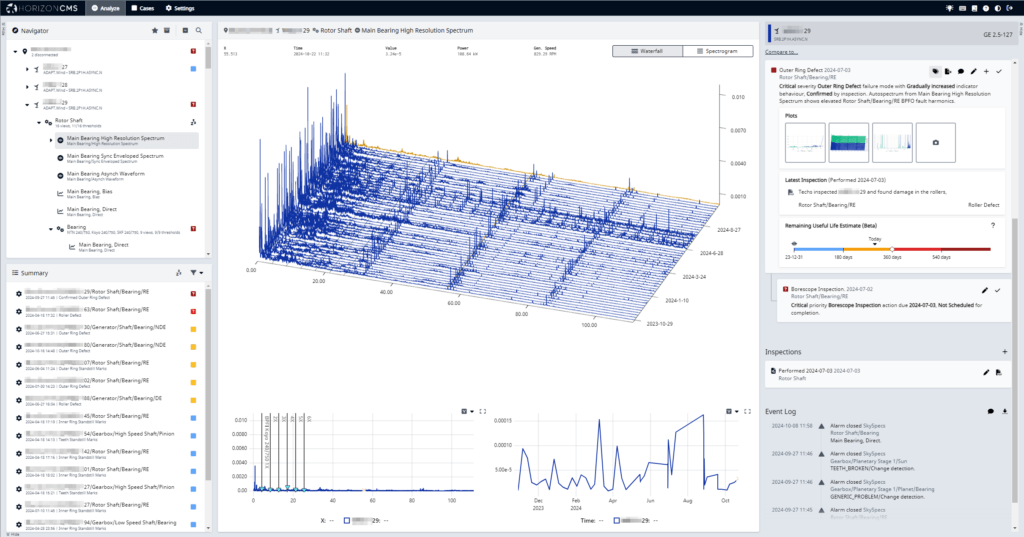

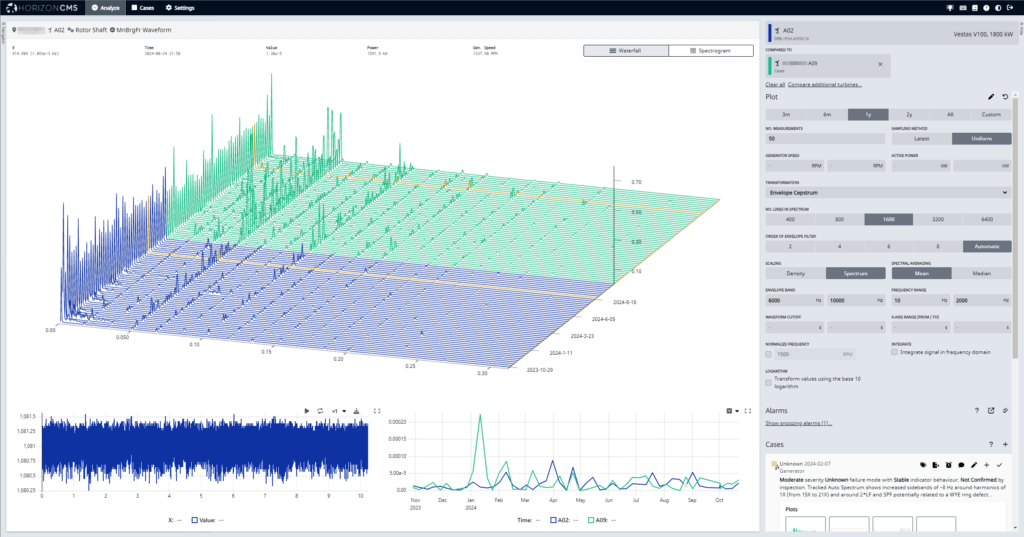

Advanced diagnostic toolbox and efficient alarm handling

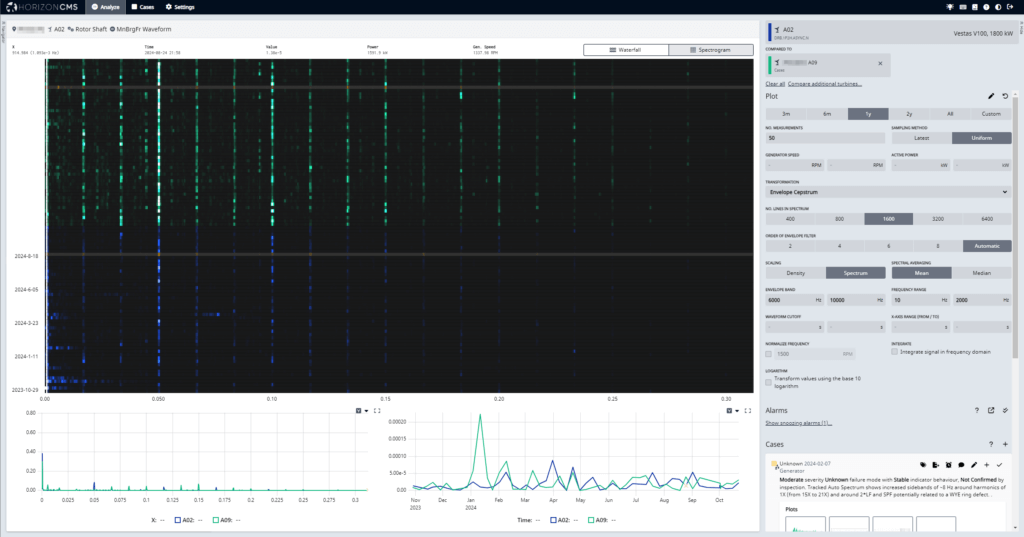

Horizon CMS offers a cutting-edge experience in condition monitoring, with streamlined and intuitive workflows for every aspect of the process. From alarm management and diagnostic analysis to case handling, reporting, and system configuration, each task is designed for maximum efficiency. For diagnostics, Horizon CMS rapidly converts hundreds of raw waveforms into meaningful 3D waterfall plots or spectrograms, providing a clear visualization of fault signatures. Users have access to a wide range of transformation tools and customizable plot parameters, allowing for precise validation of alarms. Powered by an extensive kinematic library, our advanced cursor system enhances detection accuracy, delivering superior insights into equipment performance.

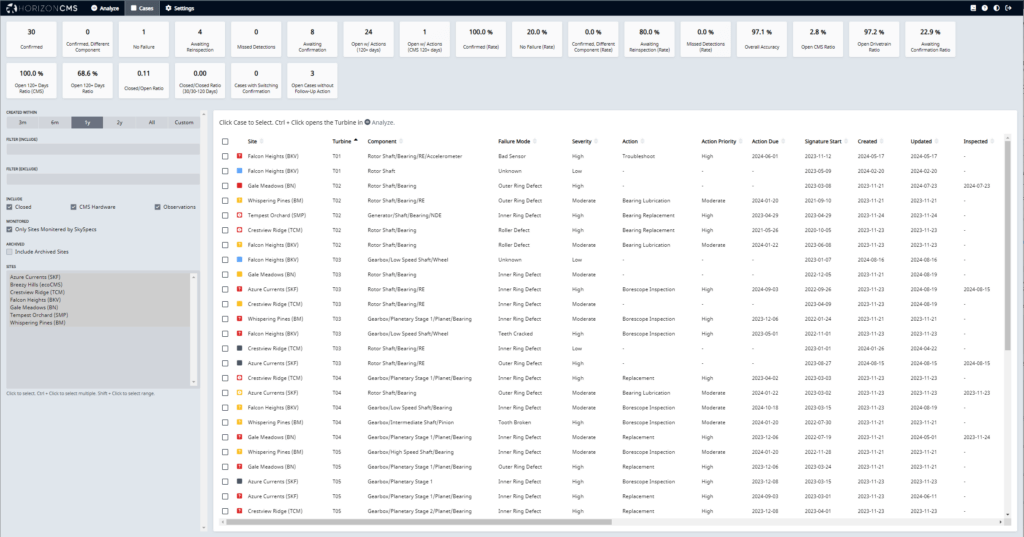

Powerful case system and reporting tools included

Our powerful case management and reporting tools are built-in, offering a seamless integration into your daily monitoring operations. Effortlessly register and track diagnostic cases through an intuitive workflow. Save and recall plots for easy tracking of fault progression, while generating maintenance recommendations in real-time. With just a few clicks, you can create comprehensive reports directly within your workflow. The case browser provides a fleet-wide overview, advanced data filtering, and built-in diagnostic KPI tracking, allowing you to generate reports or export data from any case selection with ease.

Vibration, SCADA, Oil sensors - Integrate everything

Vibration sensors are the preferred industry choice for drivetrain condition monitoring. When combined with other data sources in Horizon CMS, asset operators can unlock significant additional value.

All Major CMS Hardware Brands

Horizon CMS supports TCM, BKV, Bently Nevada (System1, ADAPT.Wind), Bachmann, SKF, ecoCMS, and SMP.

Operational Context

SCADA data can offer CMS engineers real-time insights into site operations, helping to understand performance states, check derate status, and read error codes.

Non-Vibration Drivetrain Monitoring

If your turbines lack a vibration monitoring system, SCADA data can offer limited coverage for main and generator bearings, while oil debris monitoring can provide some early detection of gearbox faults.

Enhanced Severity Tracking

Auxiliary drivetrain sensor data streams, such as SCADA temperature channels and gearbox oil debris sensors, can provide improved severity tracking and additional warning mechanisms.

Extended Monitoring Scope

SCADA-based outlier detection can expand monitoring beyond drivetrain components i.e. cooling systems, pitch motors, etc..

Customize your monitoring configuration

Horizon CMS is delivered as a complete, out-of-the-box monitoring solution, but is highly customizable to meet your needs. Horizon CMS includes features like a favorites system, dark mode, alarm notification emails, and saved plot transformations. Advanced users can go even further by defining custom failure indicators and adjusting alarm thresholds to fine-tune their monitoring setup.

CMS for every situation

Daily monitoring for self-performing sites

Self-performing means taking on unlimited risk, with drivetrain components posing some of the greatest threats to your wind farm’s financial performance. Condition monitoring is the best investment to mitigate that risk. With daily monitoring, vibration analysts (CMS Engineers) review alarms and track ongoing cases, ensuring that actionable findings are reported promptly. Regular, aggregated reports and prioritizations are conducted in close collaboration with your site operations team, keeping you informed and proactive.

Shadow monitoring for warranty and full-scope service agreements

Is your turbine manufacturer being too conservative or taking unnecessary risks? Is your site manager overwhelmed and in need of customer support to prioritize? Independent monitoring during FSA or warranty periods can unlock significant gains. Was your turbine derated or stopped too soon? Could that gearbox replacement have been pushed to the next fiscal year? Without independent assessments, you may not know where you’re losing out.

Shadow monitoring offers monthly or quarterly health assessments alongside the manufacturer’s monitoring, giving you greater transparency and the ability to challenge and guide their site operations team.

EoW health check

Maximize your claim potential by identifying drivetrain issues early using vibration sensor data. Optimize your EoW walkdown campaigns with targeted, data-driven insights—directing your teams to inspect only where it matters, on the turbines that need it most.

Learn more about our Tech-Enabled Services for Condition Monitoring here.

Tech-enabled services or just software, you decide

Leverage our world-class monitoring team

Whether you need full-scope monitoring, shadow services, or end-of-warranty health checks, our expert team has you covered. We collaborate closely with your operations team to drive proactive measures and maximize ROI. Our specialists assist with troubleshooting, prioritization, and provide expert guidance to support and empower your maintenance teams.