In the wind industry, it is widely accepted and understood that SCADA data can be used as a valuable input to condition monitoring algorithms. The data is particularly useful for the analysis of trends in temperature signals and has been shown to be an effective way to detect faults early, allowing proactive inspection and maintenance to be planned in a timely manner.

However, due to the dynamic operating characteristics of wind turbines, including variations in ambient conditions as well as the turbine load, the thermal response of the individual components is complex. Accurate fault detection requires simulation of the turbine in its healthy state of operation, then comparison of the simulated behavior with measured temperatures in order to identify outliers and deviations.

Previous work has shown that machine learning techniques such as neural networks can be used to simulate the relationship between input variables and response variables. However, these techniques can have some limitations, such as lack of transparency, the requirement to use long training sets to cover seasonality and over-fitting.

With this in mind, the SkySpecs Performance team has demonstrated that physics-based models can be used to model the thermal response of components inside the wind turbine with full transparency, low complexity, and high accuracy. By using this approach, a number of faults can be detected across a wind turbine portfolio, including gearbox, main bearing, and generator damage.

Once early faults are identified, proactive inspection and repair can take place before the repair price tag grows exponentially. The team is now able to apply this fully automated model to analyze large fleets of wind turbines.

The science behind the method

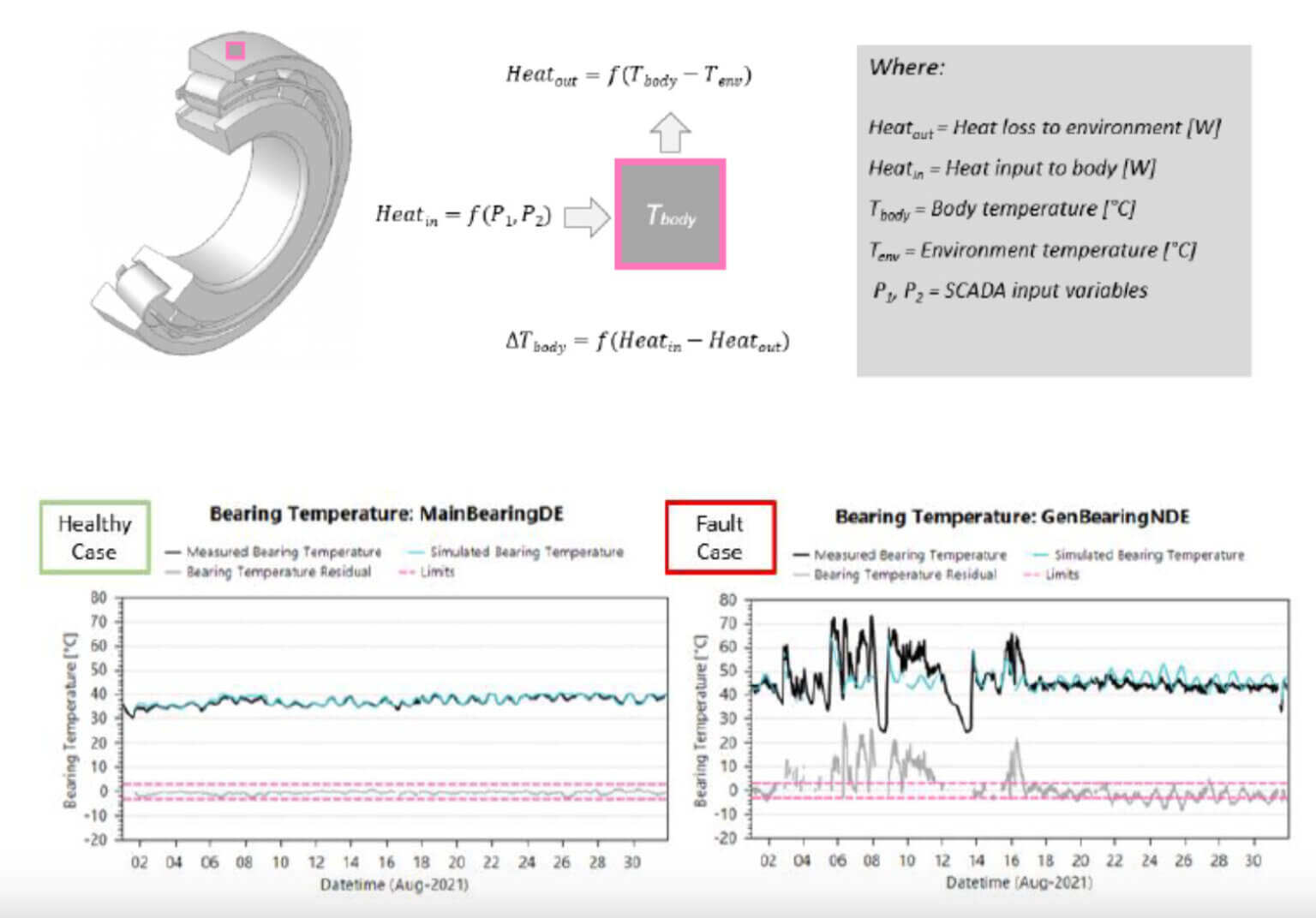

The SkySpecs team uses physics-based models to simulate the thermal behavior of various components within the wind turbine, with specific focus on drivetrain components including the main bearing and generator bearings. The model also describes the relationship between heat input and temperature response of the system components using coefficients to describe heat transfer rates, heat coefficients, and thermal inertia.

As shown in the above image, SCADA variables P1 and P2 are used to calculate the heat input to the system. The heat loss is calculated as a function of the temperature difference between the body and its environment.

The rate of change of body temperature is then calculated using a thermal inertia coefficient, calculated for each individual turbine. All coefficients are trained using reference datasets from relatively short time periods, and used to predict future temperature responses of the same components. Prediction and measurement are finally compared to produce residual values, which in turn were used to detect the presence of component faults.

The results

Due to the high level of automation achieved and the use of available SCADA logs accessed through the existing data infrastructure, the SkySpecs team is able to offer a scalable and cost effective solution to regularly monitor a large global fleet of wind turbines. The capability for detecting a wide range of faults from critical mechanical systems in the wind turbine can significantly contribute to improvements in overall fleet reliability and availability, ultimately reducing the costs for services and related logistics.

Learn more below about how these models could be implemented for your wind turbine fleet by scheduling a call with our SCADA experts.

Learn more about how this model could be implemented for your wind turbine fleet by scheduling a call with our SCADA experts.