As the wind energy industry continues to evolve and turbine sizes grow larger with each new generation, understanding the lifespan of wind assets before requiring major repairs or replacements remains a key challenge- especially given the limited number of units for each model in operation.

What we do know is that premature failure of the main wind turbine subsystems such as generators, gearboxes, or transformers can result in considerable periods of downtime, production losses, and expensive repairs. This can leave owner operators open to significant financial liability. Decisions concerning the choice of service contract, preferred service providers, level of insurance to carry, required spare parts and tooling, or whether to extend the operational life of a turbine are all strongly influenced by expectations of the future reliability of the turbine. This makes the need and want for predictive maintenance all the more important. The capability to project failure rates over relatively long time periods ranging from one to ten years becomes extremely important.

While classical reliability theory including well proven techniques such as MTTF (Mean-Time-To-Failure) assessment and Weibull modeling is readily available to address such problems, the practical application of such techniques is often difficult to use for a variety of factors. These factors include the high effort required to create well classified historical failure datasets, resources and expertise to do this type of work, or even the complete absence of such failure data, which can all hamper these efforts.

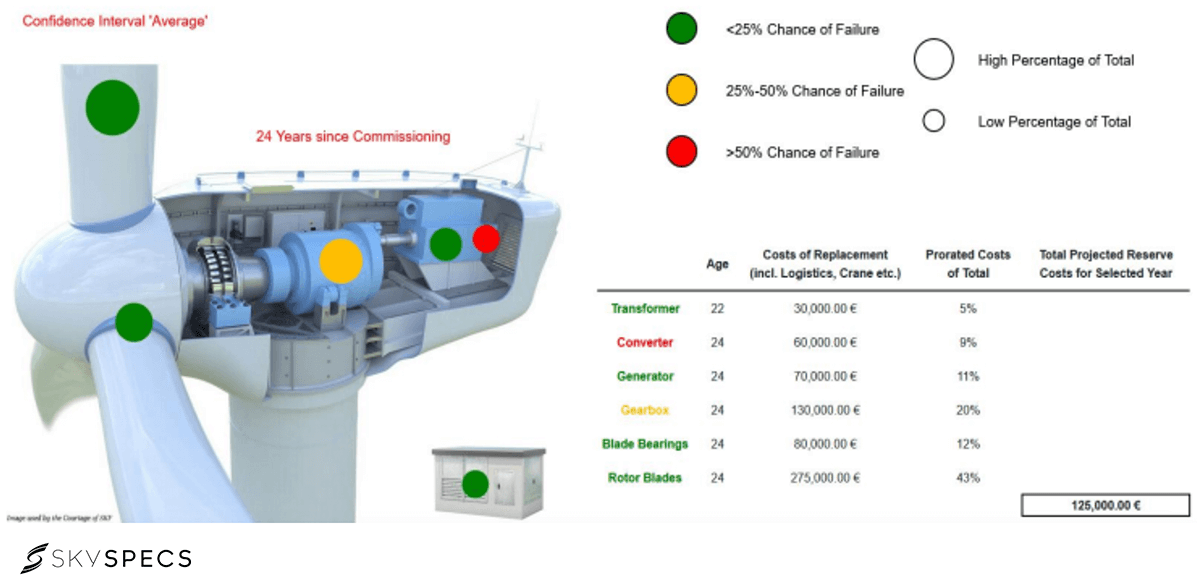

With these challenges in mind, the SkySpecs Performance team developed a method to deal with these limitations in a pragmatic manner, allowing component failure risk to be calculated with quantified levels of uncertainty. The team successfully implemented the method for an aging fleet of around 100 turbines, and used the results to provide decision making support for next steps on maintenance management for the fleet.

With this model, the team is now able to demonstrate how relatively small sets of failure data can be used to predict long term failure rates with defined levels of uncertainty. The team is now working on utilizing these results to develop a system that helps operators better assess and manage financial risks associated with spare parts and maintenance planning.

The Science Behind the Method

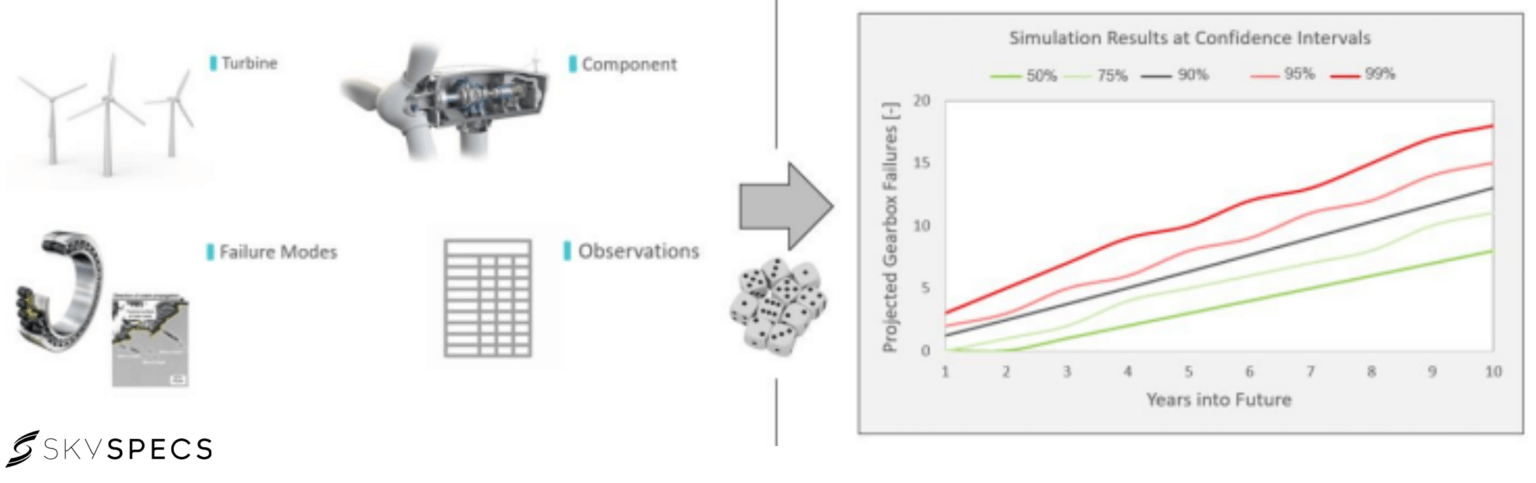

The SkySpecs team started building this method by first gathering master data from the portfolio of about 100 turbines, all of the same type from the same manufacturer. Priority systems were chosen, including gearbox, generator, transformer, blades, and blade bearings.

The team then examined service records for the turbines, and a database was compiled including all major failure events leading to complete repair or replacement of the chosen systems.

A statistical model was then developed, capable of calculating the overall failure probability for each of the systems for a time period of up to 10 years into the future. This method allows taxonomy to be defined with varying levels of detail. It’s also tolerant to small input datasets and is adaptive, increasing in accuracy with the addition of any future failure events.

The Results

By relaxing typically strict requirements concerning taxonomy and failure mode classification, a solution was developed that can be deployed productively within a relatively short timescale. Limitations on the quality and quantity of available input data are accepted and considered in failure rate predictions by stating the confidence intervals associated with all results.

Over time as the input data quality improves, so do the confidence intervals. Also, as the understanding of specific failure mechanisms improves, the data classification may be progressively updated for increasing results accuracy.

By embedding this model into operational processes and using it to provide fleet-level reliability projections that are updated monthly, we can provide the fleet operator with valuable insights that are used for strategic decision-making.

While the topic of researching wind turbine failure rate analysis and reliability projection is not new, it is of strategic and financial importance. There have been several well known, large scale funded projects aimed to advance this capability and area of the field. But due to the barriers discussed, it has always been difficult to address the lack of high quality input data.

The pragmatic application of fundamental reliability theory can lead to huge improvements in O&M strategy, and significant cost savings at many levels of the value chain. This method and approach is unique with its tolerance to imperfections in data quality, can be rolled out quickly at a low cost, and has been proven to provide immediate value in the practical use case of the 100 turbine fleet.

Learn more about how this model could be implemented for your wind turbine fleet by scheduling a call with our Performance team.